Product Description:

The PCB Cleaning Machine is an advanced and efficient solution designed to remove stains and contaminants from printed circuit board assemblies (PCBA) using a specialized chemical cleaning agent. Engineered for precision and reliability, this machine ensures thorough cleaning, rinsing, air drying, and drying processes, making it an indispensable tool in electronics manufacturing and repair industries.

One of the key features of this PCB Cleaning Machine is its ability to operate within a gas pressure range of 0.4-0.6Mpa, providing optimal pressure to facilitate effective cleaning without causing damage to delicate circuit components. Constructed from high-quality stainless steel, the machine retains its original color, ensuring durability and resistance to corrosion even after prolonged use in demanding industrial environments.

The cleaning process is meticulously designed to enhance the quality and longevity of PCB assemblies. It begins with the application of a chemical cleaning agent that targets and dissolves various types of stains and residues commonly found on PCBAs. Following this, the machine performs a rinsing stage to wash away the loosened contaminants, ensuring that no chemical residues remain. The subsequent air drying phase utilizes controlled airflow to remove moisture quickly and efficiently, preventing oxidation and other moisture-related issues. Finally, the drying stage completes the process, preparing the PCB for immediate use or further assembly.

In terms of specifications, the machine accommodates PCB sizes up to a maximum of 330x250mm, making it suitable for a wide range of board dimensions commonly used in electronics manufacturing. This size specification ensures versatility, allowing the cleaning of various PCBA types without the need for multiple machines or setups.

The machine is also equipped to handle diluent liquid with a heat temperature range from room temperature (RT) up to 99℃. This feature allows operators to adjust the temperature of the cleaning solution to optimize stain removal efficiency for different types of contaminants and PCB materials. Additionally, the concentrate liquid tank capacity is 30 liters, providing ample volume for extended cleaning operations without frequent refilling, thus enhancing productivity.

Wash time is another critical factor in the cleaning process, and this machine offers adjustable wash times ranging from 5 to 20 minutes. This flexibility enables users to tailor the cleaning duration based on the severity of staining and the specific requirements of the PCB being processed, ensuring thorough cleaning while minimizing cycle time.

Overall, the PCB Cleaning Machine combines robust construction, precise control over cleaning parameters, and versatility in handling various PCB sizes and contamination levels. Its integration of chemical cleaning with effective rinsing and drying stages ensures that PCBAs are restored to optimal condition, free from stains and residues that could impair performance or reliability.

Whether used in small-scale repair shops or large-scale electronics manufacturing facilities, this machine stands out as a reliable and efficient solution for maintaining high-quality standards in PCB assembly cleaning. Its thoughtful design and comprehensive features make it an essential asset for professionals seeking to enhance the quality and longevity of their electronic products.

Features:

- Product Name: PCB Cleaning Machine

- Model: SME-PC560

- Gas Pressure Range: 0.4-0.6Mpa

- Specification: Maximum PCB Size 330x250mm

- In Line Type: No

- Color: Original Color Of Stainless Steel

- SME-5600T main application: Car electronics PCBA, Military PCBA, Aerospace PCBA, Telecom PCBA, Medical device PCBA, Digital meters PCBA

- Machine Features:

- PCB Dry Temperature Range: Room Temperature to 99℃

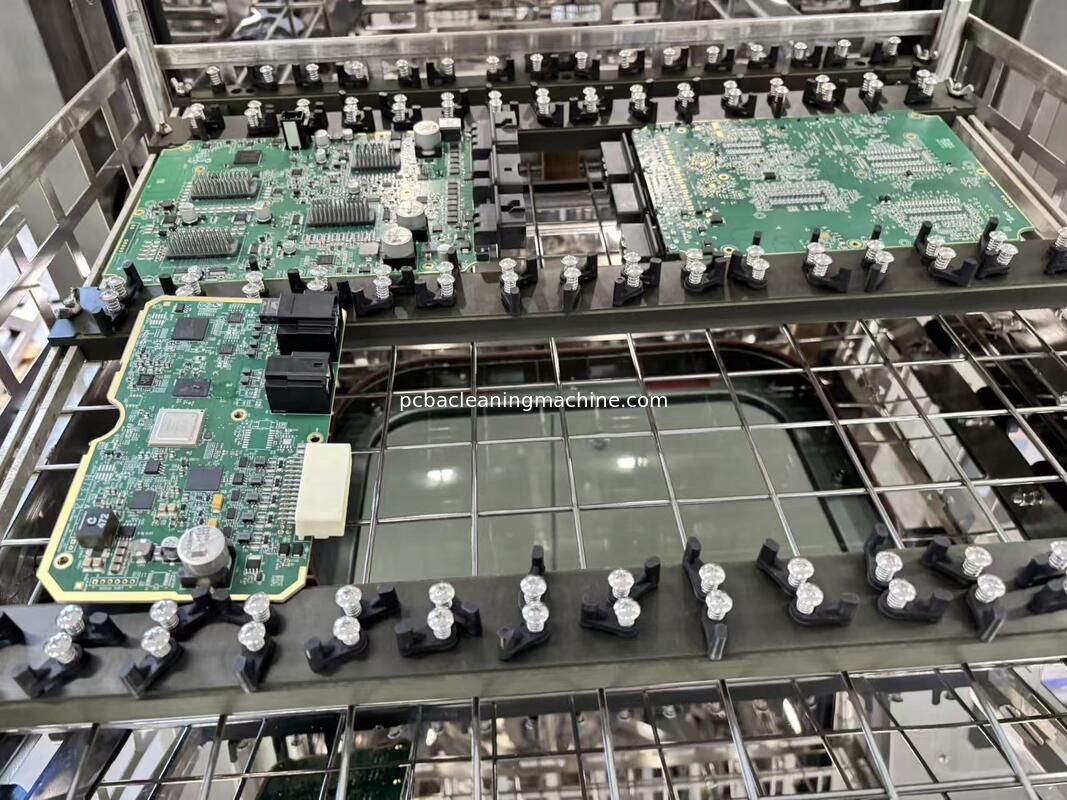

- Wash Basket Size: L610 x W560 x H100 (mm) with 2 layers

Technical Parameters:

| Model |

SME-PC560 |

| Machine Type |

Automated Cleaning Equipment |

| Color |

Original Color Of Stainless Steel |

| Cleaning Process |

Cleaning, Rinsing, Air Drying, Drying |

| In Line Type |

No |

| Usage |

Remove The Stains On PBCA Using A Chemical Cleaning Agent |

| Cleaning Fluid |

60CC |

| Stencil Size |

L610*W610*T100mm As Max |

| PCB Thickness |

0.5~3.0mm |

| Gas Pressure Range |

0.4-0.6Mpa |

| Rinse Times |

1~99 |

| PCB Dry Temperature |

RT~99℃ |

Applications:

The Automatic machine equipment for cleaning PCBA, model SME-5600L, is an advanced PCB cleaning machine designed and manufactured in China. Certified by CE, this machine ensures high standards of quality and safety. With a minimum order quantity of just 1PCS and a competitive price of USD 38,000.00, it is an excellent investment for electronics manufacturers seeking efficient and reliable cleaning solutions. The SME-5600L comes packaged securely in a wooden box to ensure safe delivery, with a delivery time of approximately 4 weeks and payment terms based on T/T.

This PCB cleaning machine is specifically designed for cleaning PCBs with thickness ranging from 0.5mm to 3.0mm and supports stencil sizes up to L610*W610*T100mm. The machine boasts a large wash tank capacity of 18L and a diluent liquid tank capacity of 60L, facilitating extended cleaning cycles without frequent refilling. Operating on AC380V 3P, 50/60HZ with a power consumption of 30KW and an air pressure requirement of 0.5Mpa, it delivers powerful and consistent cleaning performance. Additionally, it features a flow rate of 200~400L/Min to ensure thorough and efficient removal of contaminants from PCBA surfaces.

The SME-5600L is perfect for a variety of application occasions and scenarios within the electronics manufacturing industry. It is ideal for inline and offline PCB assembly cleaning processes, even though it is not designed as an in-line type machine, it fits seamlessly into production lines requiring batch cleaning. Its simple operation allows factory operators to quickly train and integrate it into daily workflows, improving overall efficiency. The high cleanliness level achieved by this machine ensures that PCBs are free from flux residues, oils, dust, and other contaminants, which is crucial for maintaining product quality and reliability.

This cleaning machine is especially useful in scenarios where high output and consistent cleaning quality are mandatory, such as mass production environments in electronics manufacturing plants. The original stainless steel color and robust build quality make it suitable for industrial settings where durability and easy maintenance are important. Manufacturers producing consumer electronics, automotive electronics, medical devices, and telecommunications equipment will find the SME-5600L highly beneficial for meeting stringent cleanliness standards.

With a supply ability of 10 sets per month, this PCB cleaning machine supports scalable production needs and can be procured for both small and large-scale operations. Its key selling points include simple operation, high cleaning efficiency, and large output capacity, making it a valuable asset for electronics manufacturers aiming to enhance product quality and production efficiency. Whether used in prototyping labs, repair centers, or high-volume manufacturing plants, the SME-5600L reliably delivers exceptional PCB cleaning performance.

Customization:

Introducing the Automatic machine equipment for cleaning PCBA, model SME-5600L, a state-of-the-art PCB Cleaning Machine manufactured in China with CE certification. This automated cleaning equipment, model SME-PC560, is designed to effectively remove stains on PCBA using a chemical cleaning agent, ensuring high-quality results for your production line.

With a PCB thickness compatibility ranging from 0.5 to 3.0mm, this machine is tailored to meet diverse cleaning needs without compromising performance. The SME-5600L is not an in-line type machine, providing flexible installation and operation options.

One of the key features of this PCB Cleaning Machine is its lower operating costs. Equipped with a built-in filter, the dilution solution can be reused multiple times, significantly reducing chemical consumption. Additionally, the machine employs a compressed air blow method at the end of the cleaning process, which blows residual detergent off from the pipeline and pump, effectively saving 50% of the dilution solution.

The DI water rinse time is fully adjustable to meet ion contamination requirements, ensuring thorough cleaning and maintaining the integrity of your PCBA boards. This feature enhances the cleaning process by providing customizable rinse cycles based on specific production standards.

Each unit is carefully packaged in a sturdy wooden box to ensure safe delivery. With a minimum order quantity of just 1PCS and a price of USD 38,000.00, the SME-5600L offers excellent value for businesses seeking reliable and efficient PCB cleaning solutions.

We guarantee delivery within 4 weeks and offer convenient payment terms via T/T. Our supply ability is 10 sets per month, allowing consistent availability for your production demands.

Support and Services:

Our PCB Cleaning Machine is designed to provide efficient and thorough cleaning for printed circuit boards, ensuring optimal performance and reliability. For technical support, please refer to the user manual included with your machine, which contains detailed instructions on setup, operation, and maintenance.

If you encounter any issues during installation or use, verify that all connections are secure and that the cleaning solution used is compatible with the machine’s specifications. Regular maintenance, such as cleaning the brushes and checking the filtration system, is essential to maintain cleaning effectiveness and prolong the machine’s lifespan.

We offer comprehensive services including installation guidance, routine maintenance, troubleshooting assistance, and replacement parts. Our technical team is committed to helping you maximize the value of your PCB Cleaning Machine by providing expert advice and timely support.

For optimal results, ensure that the cleaning parameters are set according to the type and size of the PCBs being processed. Always follow safety protocols when handling cleaning chemicals and operating the machine.

We recommend scheduling periodic service checks to inspect mechanical components and update software, if applicable, to keep your PCB Cleaning Machine operating at peak efficiency.

Packing and Shipping:

Product Packaging:

The PCB Cleaning Machine is securely packaged to ensure safe delivery and to prevent any damage during transit. It is enclosed in a sturdy, custom-designed cardboard box with ample cushioning materials such as foam inserts and bubble wrap. The packaging includes clear labeling with product information, handling instructions, and safety warnings. All accessories and user manuals are packed alongside the machine in designated compartments to keep everything organized and protected.

Shipping:

We offer reliable shipping options to deliver the PCB Cleaning Machine promptly and safely to your location. The product is shipped via trusted carriers with tracking available for all orders. Depending on your location, shipping times may vary, and expedited shipping options are also available upon request. Before shipment, each unit undergoes a thorough quality check to ensure it meets our high standards. International shipping is supported, with customs documentation prepared to facilitate smooth import processes.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!